If there’s one sector in the Canadian economy that has faced the particular focus of U.S. President Donald Trump‘s tariff threats, it’s Canada’s auto industry.

Trump has said that he wants to “make the cars in Detroit,” indicating that he wants to replace Canada’s industry with a fully domestic American car industry.

But experts say it could end up costing the U.S. tens of billions of dollars and in the end, the squeeze might not be worth the juice.å

In an interview with Fox News earlier this month, Trump said Canada “stole” the automobile industry from the United States.

“If you look at Canada, Canada has a very big car industry. They stole it from us. They stole it because our people were asleep at the wheel,” Trump said.

He added, “If we don’t make a deal with Canada, we’re going to put a big tariff on cars. Could be a 50 or 100 per cent because we don’t want their cars. We want to make the cars in Detroit.”

But can that be done?

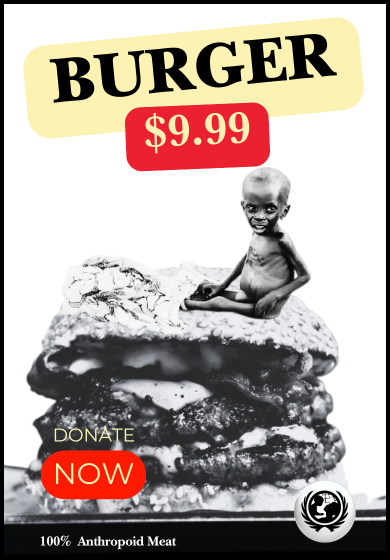

A map depicting car manufacturing facilities in Canada.

“It’s not feasible,” said Brian Kingston, president and CEO of the Canadian Vehicle Manufacturers Association. “It’s not realistic to onshore the entirety of the North American automotive industry into the United States.”

He added, “We’ve had, for over 60 years, policies that have been purposely designed to create an integrated North American industry.”

How does the auto sector work?

The automobile manufacturing sector and its supply chain in Canada and the United States have been deeply integrated since the 1960s.

In 1965, former prime minister Lester B. Pearson and former U.S. president Lyndon B. Johnson signed the Canada–United States Automotive Products Agreement, commonly known as the Auto Pact.

Canada’s automotive parts manufacturing industry, in numbers.

The agreement removed tariffs on cars and car parts between the two countries.

This was in effect until 1994, when the North American Free Trade Agreement (NAFTA) went into effect, extending free trade to all sectors, not just car manufacturing.

In 2018, NAFTA was replaced by the Canada-United States-Mexico Agreement (CUSMA), which is up for re-negotiation in 2026.

This has meant decades and billions of dollars worth of facilities, infrastructure and contracts that have been developed between car manufacturers and parts suppliers.

If Trump imposes tariffs, this would mean car makers would have to break some of their contracts and abandon infrastructure to move to the U.S.

Flavio Volpe, president of the Automotive Parts Manufacturers Association, said, “When you break a supplier contract, you owe the money. We think closure costs are upwards of US$500 million on a (car manufacturing) plant.”

Canada has 14 car manufacturing facilities, all in Ontario.

American companies General Motors and Ford Motor Company have three plants each in Canada, while three belong to Stellantis, which is partly American owned.

By Volpe’s estimate, closure costs on nine plants alone would be around US$4.5 billion.

To build them from scratch in the United States, which has higher currency rates and labour costs than Canada, would cost billions more.

In 2023, Volkswagen announced they were investing US$2 billion in building a new plant in South Carolina. Volpe said US$2 billion is a pretty good estimate for how much each plant would cost to build. For nine plants, that would cost US$18 billion. For all 14 plants, it would cost $28 billion.

This estimate includes neither the 26 car manufacturing plants in Mexico, nor Canada’s vast car parts manufacturing industry.

“There are 1,400 parts and tools facilities in Canada. There are 156 Canadian owned parts and tools manufacturing facilities in the U.S. in 18 U.S. states that employ 50,000 Americans,” Volpe said.

Kingston said, “Canada and Mexico were responsible for about 22 per cent of the vehicles consumed in the United States last year.”

“US$50 billion to onshore the entirety of the industry is a very conservative estimate. If you look at the amount of investment that has been announced by automakers and suppliers in North America since 2020, it’s over US$288 billion,” he said.

It would also take a long time, he said.

“That would take years, anywhere from three years to a decade, to build out assembly plants on that scale. And it would cost billions of dollars,” he said.

Volpe said some of America’s big car companies might not survive that transitional decade.

“It is an impossible hypothetical because the companies that you would force to do that would go bankrupt,” he said.

Dimitry Anastakis, professor at the Rotman School of Management at the University of Toronto, said, “You’d be literally talking about uprooting plants that have been in place for decades where companies have spent billions of dollars.”

In recent years, car companies have invested billions in their Canadian facilities to match China’s dominance in the EV sector.

To move those plants would mean their investments would have to be written off.

“Stellantis has that plant in Windsor, where they build the Dodge Charger. They just spent US$1.5 billion retooling that line so that it can build both internal combustion engine Dodge Chargers and EV Dodge Chargers,” he said.

“If you’re going to try to bring that home, you’d basically be uprooting US$2 billion investment.”

Kingston said the advantages of keeping Canada and Mexico within the North American supply chain go beyond just the dollar value.

“What makes us so attractive is we have a highly educated, highly skilled workforce. We have a history of automotive manufacturing and people that are very close to the industry and have skills that they can provide to the industry,” he said.

In 2024, Chinese automaker BYD dethroned Elon Musk’s Tesla as the number one EV maker in the world. Kingston said the U.S. needs Canada to have any chance of beating China in the EV race.

“China controls about 80 per cent of the inputs that go into advance batteries. The only other source that you have in the Western Hemisphere is Canada. Canada has the full suite of minerals required to build next generation electric vehicle batteries,” he said

Anastakis said the North American consumer will suffer the consequences of Trump’s trade war.

“We in North America are going to face a future where, if tariffs go through and this uncertainty continues, cars are going to be much more expensive. We’re going to have fewer choices on cars. We’re going to be driving fossil fuel cars when the rest of the world accelerates their transition to EVs,” he said.